With the advancement in computer technology these days, many industries are benefitting from state-of-the-art precision linear stages in motion solutions. These mechanisms allow more accurate movements involved in a lot of processes in manufacturing, giving rise to equally high-tech and precise end-products such as equipment and gadgets.

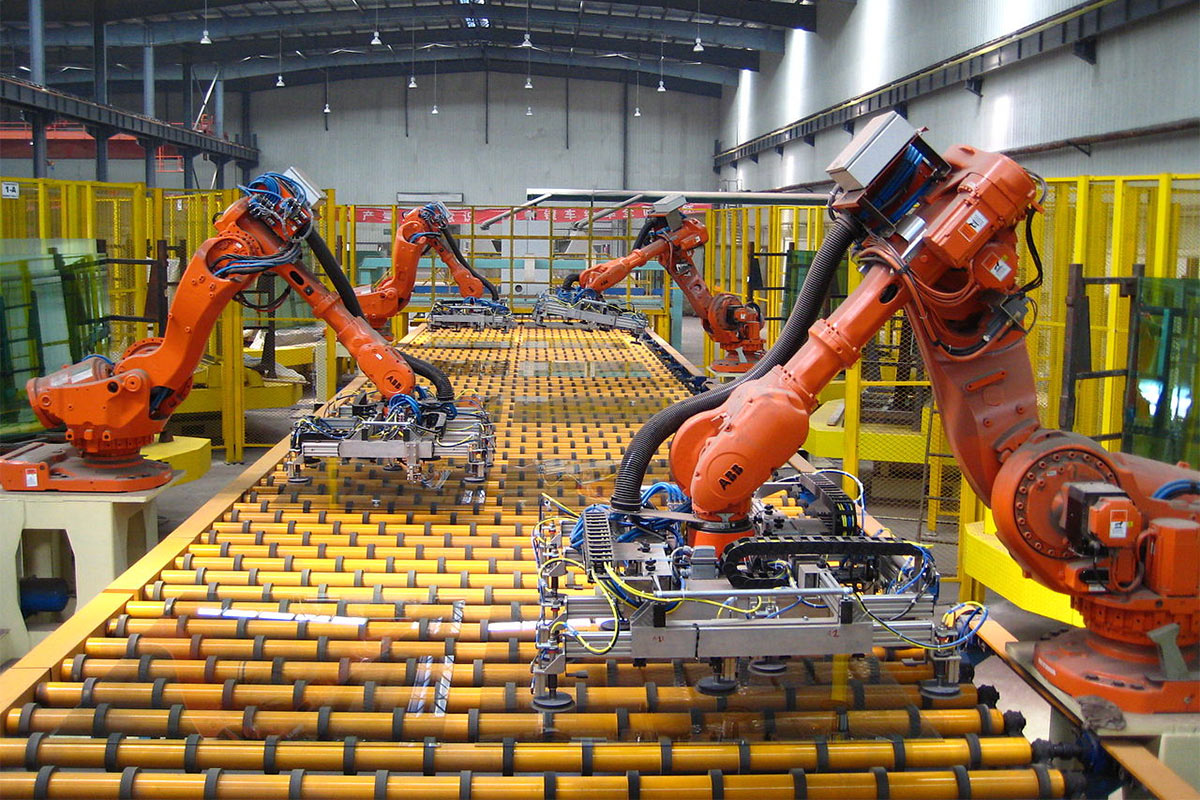

Precision linear stages are also extremely useful in many tasks and aspects of automated operations, usually involving machines or robots. They allow work to be done more efficiently and tasks to be carried out more consistently—achieving increased output without sacrificing accuracy and quality.

Understanding Precision Motion Control Systems

Linear stages are platforms that provide precise, automated positioning either on a single axis or two axes (XY stage). In a linear stage, each axis limits six degrees of possible movement (X, Y, Z, roll, pitch, and yaw) to a single one, or along a straight line. This movement is made possible through a set of linear bearing guideways attached to a base that provides stable support.

Linear bearing guideways can be constructed in a variety of ways, such as through ball recirculating bearings, air bearings, or cam followers or vee wheels. As the payload is restricted to one degree of movement, the next job of the system is to actuate the payload and enable precise, minute linear motion along the guideway. Utilizing a linear motor to achieve such incremental movement is considered to be the most precise among many possible linear actuator methods.

Motion Control Systems in Daily Life

High-precision motion control may seem like a very technical concept, but in reality, many aspects of ordinary life rely on such technology. There are a lot of industries where precision linear stages are used in effective and efficient motion control solutions.

Health and biochemical industries utilize motion control systems in tasks such as automated and precision liquid handling. These involve machines that aspirate, move, and dispense liquids from one container to another. Such processes are essential in diagnostic procedures like genomic sample preparation, high-throughput screening, immunoassays, PCR (polymerase chain reaction) amplification, and aliquoting.

Motion control solutions should be advanced and stable enough to provide high speed output, to prevent errors due to undesirable movements or jerking, as well as to provide quiet and precise repetitive operation. Such solutions have greatly contributed to accuracy of medical findings as well as to the safety of humans in situations where hazardous chemicals are being handled.

The microscopy industry is related to laboratory healthcare services and processes, but also serves a wider range of other applications. Precision motion control is of utmost importance in the microscopy industry, where automated imaging and focusing are critical in analyzing materials, samples, and other objects. Forensic science, for instance, is an exciting and evolving area where microscopy is constantly being utilized.

Manufacturing industries also benefit largely from high-precision motion control systems in processes such as those involving lasers. Cheaper but more effective lasers are now easily available and used in various applications. Motion control solutions are vital in making many laser-based processes possible. For instance, laser marking is one of the most basic and simple actions that require high-precision motion. The laser beam destroys a very superficial layer of surface material on an object to leave an impression or mark for identification or other purposes.

Laser machining or cutting, meanwhile, is another process that many people may be familiar with. This is where a material is manipulated and cut using laser, from large items such as sheet metal to extremely minute levels like heart stents for medical procedures. Laser annealing or sintering, meanwhile, alters an object’s surface and causes a transition in the basic properties of the material. All these are made possible using precision motion control systems.

Advancing Motion Control Systems

As the demand for extremely high-precision, accurate, and reliable end-products grow, so does the need for electronic components that possess the same qualities. Thus, designers and providers of linear stages, micro motors, and motion control systems are constantly being challenged to improve quality and harness the latest technologies available today.